ENGINEERING DEPARTMENT

Feasibility & Engineering

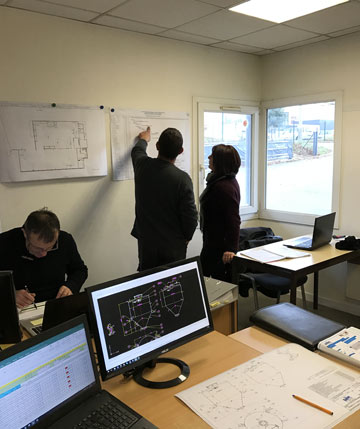

Design capability for all your boilermaking, process, and assembly projects. From the project phase to final realization, including design, development and industrialization, our project teams are a source of innovative solutions at every stage.

Our software :

- SolidWorks © : 3D

- Autocad © : 2D

Calculations

- Pressure: PED Directive 2014/68/EU

- Structure

- Pipe sizing

- Thermal

Functional Analysis

Project Definition

Jane Candy

"Lead Coder"The engineering department of Métal Performances is at your side at each stage of your industrial project. So that you make the right engineering choices, our sales team will meet you to visit your site, and initiate studies according to your drawings or your pre-defined specifications. Our technicians then take over for the pre-project, using a functional analysis or diagram to define your needs, and the scope of our work. Finally, our teams commit to providing you with documented technical and commercial proposals in accordance with a validated schedule.

Solutions adapted to your needs

Design

Jane Candy

"Lead Coder"Métal Performances is committed to designing industrial equipment in accordance with your drawings or the results of a project defined with you. Our engineering department has the capability to produce design reports (structure, hydraulic, thermal), layout drawings, lifting studies, diagrams and P&ID, 2D or 3D construction drawings integrating functional, dimensional and design aspects, choice of materials, compliance with standards and regulatory requirements (for pressure vessels). The engineering department is available at all phases of the project to answer your requests for modifications.

Efficient Scheduling

Project follow-up

Jane Candy

"Lead Coder"Our teams are dedicated to carrying out your industrial project to the highest standards. The appointed project manager will coordinate the various team members and supervise scheduling in conjunction with our production manager. All resources, both human and material, including purchasing, will be optimized. At your site, our works supervisor will ensure that the work is carried out according to the schedule. He will do this in collaboration with your representative, taking into account worksite and production factors, and interacting with the other trades involved in the operations. The project is deemed complete once the work performed by Métal Performances has been formally accepted.

FEASIBILITY AND ENGINEERING

MANAGING YOUR PROJECTS

Design capability for all your boilermaking, process, and assembly projects. From the project phase to final realization, including design, development and industrialization, our project teams are a source of innovative solutions at every stage.

FUNCTIONAL ANALYSIS

PROJECT DEFINITION

"Lead Coder"The engineering department of Métal Performances is at your side at each stage of your industrial project. So that you make the right engineering choices, our sales team will meet you to visit your site, and initiate studies according to your drawings or your pre-defined specifications. Our technicians then take over for the pre-project, using a functional analysis or diagram to define your needs, and the scope of our work. Finally, our teams commit to providing you with documented technical and commercial proposals in accordance with a validated schedule.

SOLUTIONS TO FIT YOUR NEEDS

DESIGN

"Lead Coder"Métal Performances is committed to designing industrial equipment in accordance with your drawings or the results of a project defined with you. Our engineering department has the capability to produce design reports (structure, hydraulic, thermal), layout drawings, lifting studies, diagrams and P&ID, 2D or 3D construction drawings integrating functional, dimensional and design aspects, choice of materials, compliance with standards and regulatory requirements (for pressure vessels). The engineering department is available at all phases of the project to answer your requests for modifications.

EFFICIENT PLANNING

PROJECT MANAGEMENT

"Lead Coder"Our teams are dedicated to carrying out your industrial project to the highest standards. The appointed project manager will coordinate the various team members and supervise scheduling in conjunction with our production manager. All resources, both human and material, including purchasing, will be optimized. At your site, our works supervisor will ensure that the work is carried out according to the schedule. He will do this in collaboration with your representative, taking into account worksite and production factors, and interacting with the other trades involved in the operations. The project is deemed complete once the work performed by Métal Performances has been formally accepted.

SUPPLY CHAIN INTEGRATION

TRANSPORT

To complete our services, we can take care of transport from our Brittany factory. We provide the soft and hardware to allow our clients to manage the project logistics at their end (preparation, packaging and delivery to the site). Our teams also manage the deployment of exceptional transport for abnormal loads: preparation of handling equipment in our factory, manufacture of jigs and frames to facilitate unloading and handling at the site…

GLOBAL QUALITY APPROACH TO

ENVIRONMENTAL QUALITY AND SAFETY

Our company operates according to a global quality approach: material traceability, controls at each stage of your project, and rigorously followed procedures. Metal Performances constantly invests in employee training including strict follow-up of welder qualifications (WPS, WPQR). Safety is managed with particular attention throughout all manufacturing, handling and assembly operations: use of appropriate and optimized equipment, trained, qualified personnel (CACES), risk prevention plan tailored to the needs of sensitive sites (chemical risks, Seveso risk sites). We strive to pursue our development while reducing our impact on the environment: sorting and recycling industrial waste, following the principles of environmental accountability, and energy management.